Why outsourcing from your clean rooms all electrical grid in a Data Center?

Data Center market players need more and more to deal with scalability and quickest deployments to reach IT businesses targets. Prefabricated modular systems are a way to respond.

Different technical solutions that fit Data Center market electrical needs

As per today, different very tailor-made solutions are existing for Data Center:

As per today, different very tailor-made solutions are existing for Data Center:

- Concrete prefabricated modular systems

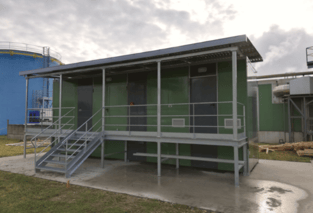

- Metal-sheet prefabricated modular systems

- Containerized modular systems

- Mobile modular systems

- Skid modular systems

Depending on local businesses, history and standards, each of them can fit for your Data Center. Solutions are generally worldwide divided by functionalities like power systems, cooling infrastructures & IT systems.

Power systems modules are including all the energy distribution architecture with the aim to supply electricity to Data Center: Medium Voltage & Low Voltage Switchgears, transformers, UPS and all auxiliary systems.

Benefits for Data Center's CAPEX

Prefabricated modular systems suppliers are negotiating with third-parties electrical materials providers and have frame agreements with them. Then, compared to conventional buildings projects bringing several providers for materials, savings costs can be huge. The fact that suppliers also design the whole complete systems from delivery grid point to consumers brings some additional savings in architecture optimization.

Prefabricated modular systems suppliers are negotiating with third-parties electrical materials providers and have frame agreements with them. Then, compared to conventional buildings projects bringing several providers for materials, savings costs can be huge. The fact that suppliers also design the whole complete systems from delivery grid point to consumers brings some additional savings in architecture optimization.

Project management costs can be reduced from 7% to 4% due to one single vendor.

Rearding quality safety aspects, Environmental Health and Safety KPI is improved on site due to minimized interventions and interfaces with other on-site activities. Site installation and shipping costs are also reduced to the fact that all equipment and interconnections are assembled in the modules that are done at factory. All the embedded system then is just a “plug and play”. For the shipping, there is one delivery for the complete engineered, installed, interconnected and tested whole module. As per extension, shipping damages and quality issues are also reduced.

FAT, commissioning & software programming for the control systems are also a cost saving matter because of factory processed test system. No site FAT & software programming is needed then for each material. Everything is done at factory for each complete prefabricated module.

A direct consequence about that previously mentioned is the reduced delivery time. Compared to conventional data center can lead to a 40% time saving. This is mainly due to standardization of modules, less manufacturing time of enclosure/integration compared to civil works and less time also for installation and commissioning.

Finally costs of real estate are also reduced knowing prefabricated modular systems are improving total footprint of infrastructures around 30% average.

Benefits for Data Center's OPEX

Flexibility and scalability: since the first early design prefabricated substations can bring scalability for the next years of operation. For example, multiple rooms can be added to first modules in order to get IT flexibility needed in Data Center market. Maintenance can also be simplified through removable panels in enclosure shells in order to remove electrical materials.

Other point is that instead of contracting different maintenance contracts with multiple vendors, one-stop shop can be agreed with prefabricated modular system provider.

Avoid overbuilt capacity: Sizing the power systems according real load can bring main savings in Opex knowing. Prefabricated modular systems can help to recover all along the Data Center life time depending on IT loads and business evolutions demands of companies.

In Summary

Prefabricated modular systems are able to support in an efficient way Data Center businesses scalability and costs optimizations. In our new economies post-Covid, this is a path to resources savings and use them more on business growth focus.