How to modernise your electrical switchboards thanks to retrofit?

With technical developments and technological innovations, you may wish to purchase a new, more efficient low-voltage switchboard. But have you thought about increasing the efficiency of your current switchboard?

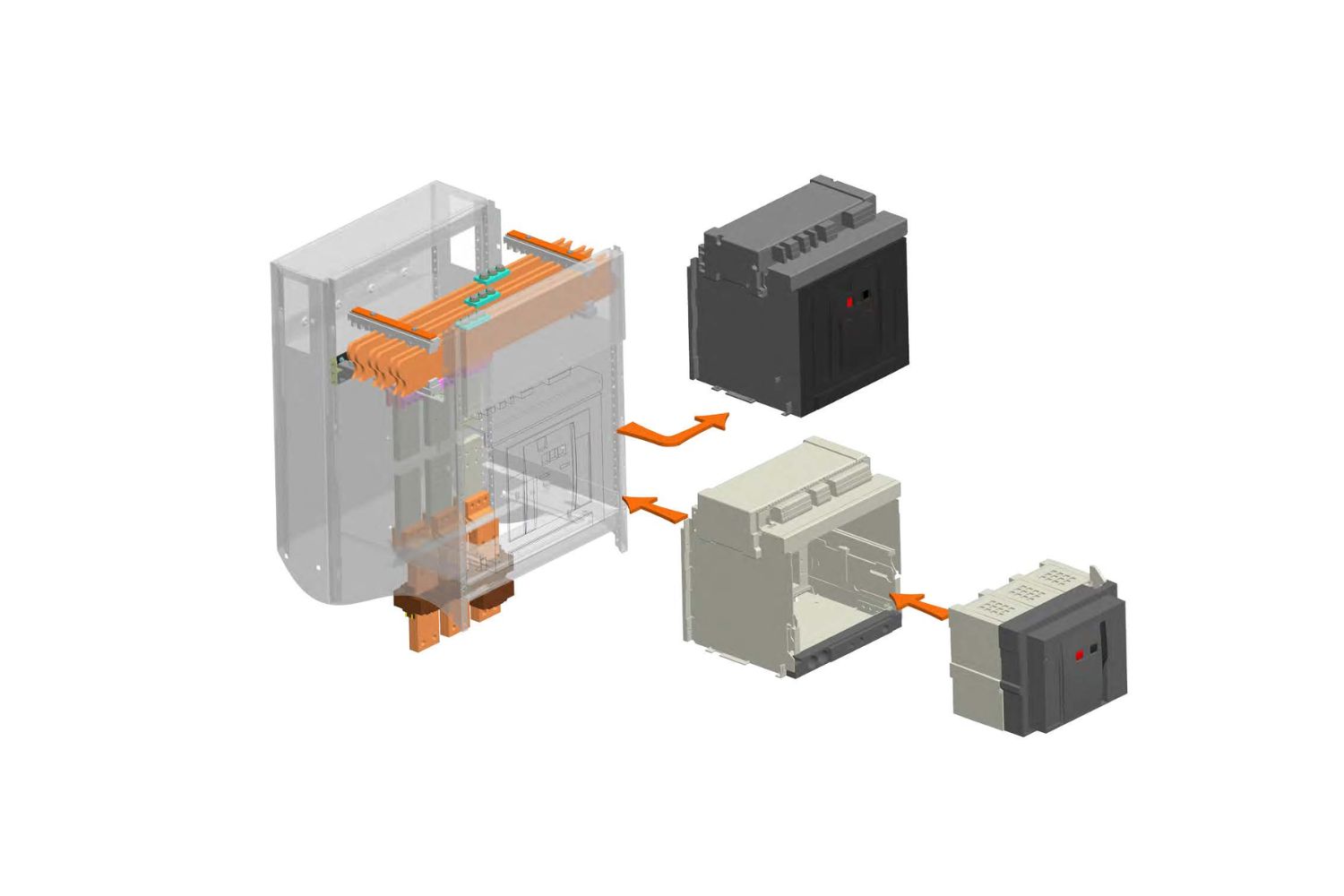

The Retrofit is the practice of replacing obsolete or defective equipment parts and components while maintaining the characteristics of the original equipment and functional unit. For COMECA Services, it is the replacement of old, obsolete or defective fixed or removable equipment with pre-designed, tested and guaranteed solutions to extend the life of your LV and MV installation.

When should you consider modifying your current low-voltage switchboard?

You should consider upgrading your installation in cases where you need (for example) more power, supervision integration, a communicating system or if your hardware is obsolete.

But before investing in the purchase of a new switchboard, ask to your manufacturer what are the possibilities of adaptation and evolution. There are solutions today to preserve your equipment while responding to your problems, and with an interesting economic balance sheet.

Replacement of obsolete components and the addition of new, modern technological enhancements make it possible to refurbish existing facilities. Operator benefit is the modernisation of the installation to higher productivity at significantly lower costs compared to the purchase of an equivalent new switchgear.

Replace your obsolete or broken components while keeping them in good condition reduces recycling costs. Removing old power cables and installing a new switchboard requires a long shutdown time, in retrofit, this time is limited. Extending the life of its equipment is also a more environmentally friendly solution.

What is the retrofit solution for an existing system?

During the life cycle of your low voltage switchboard (engineering, installation, maintenance, modernisation), the retrofit intervenes in the modernisation and/or extension phase. The method consists in removing the old equipment, carrying out an integration plan, manufacturing the solution in the factory and replacing the equipment under cut-off.

Retrofit equipment at COMECA:

- Multi-brand circuit breakers: Unelec, Schneider, Hazemeyer, Merlin Gerin, ABB, Siemens, GE, Klöckner Moeller

- Protection relays: GemStart, 2, 3, 4 and CIT to a GemStart 5

- Orchestra range: retrofit of MAP D by MAC99

- Functional units, renovation of plates and drawers

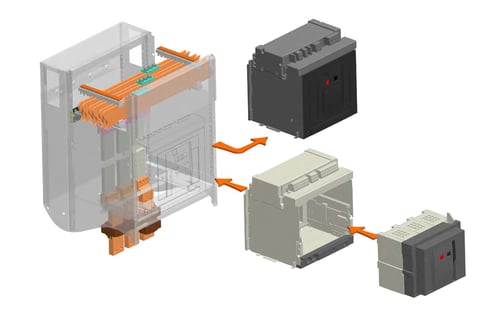

Circuit breaker retrofit

Circuit breaker retrofit

Video of a retrofit from GemStart4© to GemStart5©

How to determine the modifications to your electrical switchboard?

Modifications are determined according to your new needs and existing equipment. If your need has evolved, the Retrofit will act on all the components of the equipment in order to get the new characteristics you need for the switchboard. For example, increase or decrease the nominal current of the main busbar.

Your installation may also need to be modified for supervision or for measuring its energy consumption. Retrofit then allows you to add communication functionality for example. These modifications are possible in all fields and even with an equipment that no longer exists on the market. In this case, we will carry out a specific study to adapt the equipment using our 3D study tool to design parts.

Retrofit steps:

- System analysis: each Retrofit is a particular case and requires a thorough analysis. The aim of this analysis is to know in detail device functionalites we have to replace.

- Need identification

- Device measurement

- Integration study carried out

- On-site replacement under cut-off

What are main benefits of Retrofit?

Retrofit allows you not only to optimise your original equipment but also to extend its life. Your OEM will support you throughout the process to ensure that your installation functions properly following the modifications you have made. Update your electrical switchboard with a pre-designed, tested and validated solution to ensure a quick and easy integration into your existing installation.

Customer benefits:

- Distribution network sustainability

- Performance improvement

- Available spare parts

- Equipment modernisation

- Extend equipment life

Upgrading your equipment allows you to do predictive maintenance and prevent unexpected production shutdowns. Find out our advice in our blog post: