Retrofit of NORMABLOC switchboards for a nuclear operator

It is possible to renovate and modernise existing equipment while keeping control of your investments thanks to retrofitting. You can thus extend the life of your LV switchboards while ensuring optimal safety, reliability and continuity of service of your installations without replacing all the equipment.

To guarantee a safe and efficient installation, it is important to ensure the good health of its low voltage equipment throughout its life. Continuity of service of equipment and maximum safety are crucial to limit the risk of breakdowns and accidents. This is especially true when our customers operate in a sensitive environment where production stoppages are unthinkable and emergency interventions are unacceptable.

In the long term, the question of maintaining the characteristics of the original switchboards and the modernisation of its equipment arises. Retrofitting often provides a solution for the long-term without having to replace the entire switchboard.

In the case study below, our Comeca Services teams have carried out the retrofit with a double clamp system of a first 120 series UNELEC CNP circuit breaker for one of our customers, a major player in the nuclear sector.

The challenge: Material obsolescence in NORMABLOC panels

The final project involves the renovation of approximately 40 30-year-old NORMABLOC switchboards of type N660 with rear connection and N680 with front connection. Approximately 120 obsolete circuit breakers from the UNELEC CNP range are to be replaced. For this type of installation, seismic qualification of these new circuit breakers integrated in their columns is necessary.

Due to strict operating constraints, the work is being carried out on the switchboards in service. As with many other projects, it is not possible to completely shut down the switchboards, so the downtime must be kept to a minimum.

Obsolete UNELEC CNP circuit breaker

Obsolete UNELEC CNP circuit breaker

Our answer: study and realization of a double clamp retrofit solution for NORMABLOC switchboard

We have been the original manufacturer of the NORMABLOC switchboard for over 45 years. Our installed base represents more than 10,000 columns in the French nuclear sector.

For this project, our teams carried out a mechanical and electrical feasibility study (derating, current, short-circuit resistance, temperature rise) for circuit breaker ratings ranging from 1000A to 2000A.

The seismic qualification phase consisted of 3 steps:

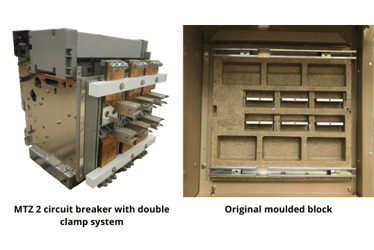

- The manufacture of the columns with the integration of the new MTZ 2 circuit breaker in each of them with the double clamp retrofit system: 1 N687 column (front connection) and 1 N667 column (rear connection)

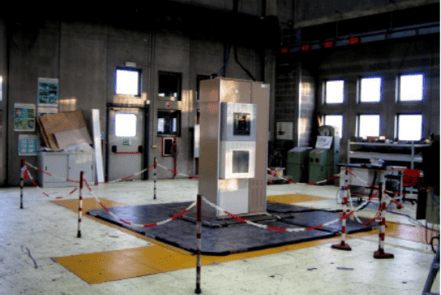

- Laboratory tests to validate the seismic qualification

Seismic test on NORMABLOC N687

- Delivery of a full report to the client indicating that the 2 assemblies have been tested and certified by an independent body (IPH Berlin) for acceptance to proceed to the next phases of the project.

The double clamp retrofit of a first MTZ 2 1000A circuit breaker was studied and designed to replace a CNP 1000 circuit breaker. We provided:

- Retention of the original moulded block - adaptation and connection between the block and the new fixed part by plug-in clamps.

- Modernisation of the circuit breaker environment and auxiliaries:

Example: the voltmeters and ammeters were replaced by a central measuring unit. - Replacement of the panels and doors.

- Creation of a replacement procedure: specific attention was paid to the protection of uninsulated live parts.

On-site work phases

Once the site visit has been carried out and the preparatory meeting and site planning meeting organised (access constraints, authorisations, prevention plan), the on-site installation of this first retrofit is carried out in several stages:

- the removal part: removal of the mobile part of the UNELEC CNP circuit breaker and its accessories

- installation of the new MTZ 2 circuit breaker and its accessories

- installation and wiring of the measuring devices and auxiliaries

- Functional tests and validation for return to service

As the operation requires work on switchboards in service, the risk analysis determines the protection methods to be used. Our teams therefore use suitable individual protective equipment (insulating gloves, face shields, insulating mats, insulating covers, flexible insulating blankets) during their work.

In summary

Our Comeca Service teams were able to design and implement the appropriate retrofit solution to meet all of our customer's needs.

The complete retrofit extends the life of the existing NORMABLOC switchboards without replacing the LV equipment.

Ensuring continuity of service and a maximum level of safety is achieved by renovating the equipment, but must also be complemented by rigorous maintenance and regular servicing.