EVOBLOC: The solution for optimising electrical ducts

In the healthcare sector, the change in regulations for sensitive equipment in operating theatres (syringe pumps, respirators, electrocardiograms, etc.) has tripled the number of circuit breakers in technical ducts, increasing safety but saturating the ducts.

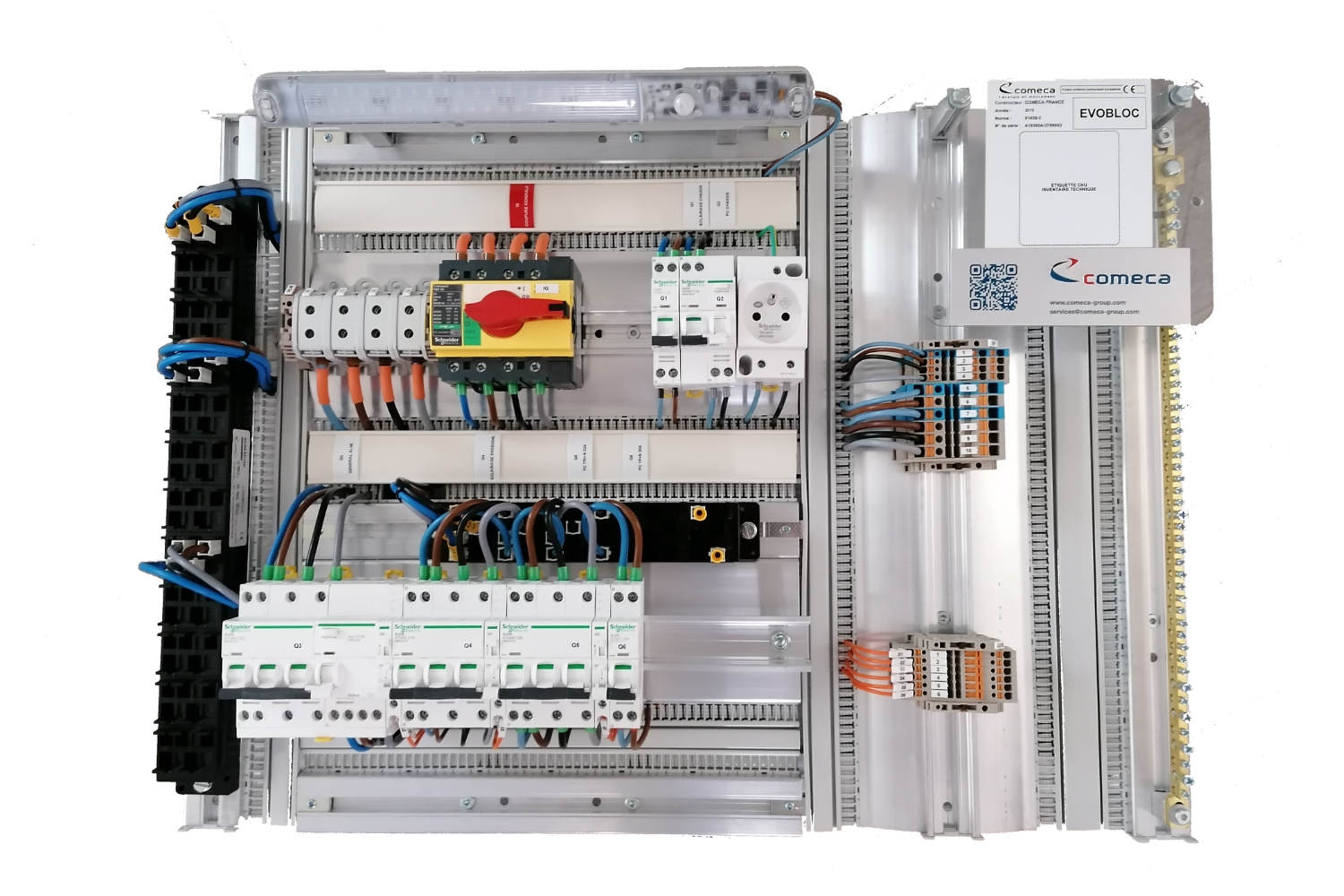

To meet these requirements, our engineering teams have developed EVOBLOC®, the first solution for optimising scalable IS 223 live equipment ducts with our new COMECLIC® distribution board. Thanks to its compactness and scalability, our EVOBLOC solution meets your future needs and current space constraints.

A tailor-made solution for hospitals

The change in regulations for sensitive equipment in operating theatres (syringe pumps, respirators, electrocardiograms, etc.) has tripled the number of circuit breakers in the technical ducts, increasing safety but saturating the ducts.

The increased safety of electrical management in hospitals limits the traditional solutions for fitting these electrical ducts:

- Difficult changes and modifications

- Creation of electrical risks

- Premature ageing of equipment

- Hot spots and confined thermal environments

Our solution overcomes these constraints: the EVOBLOC® frame is specially designed in collaboration with the hospital sector. It is a made-to-measure solution that adapts to the size of your technical ducts in compliance with the standard, and offers a number of advantages:

- Compact: its simple design makes the board adaptable to all types of technical ductwork

- Simplified maintenance: Safety is guaranteed during operational maintenance

- Scalable: the board can be extended to meet new requirements (extendable bars)

- Accessibility: operators can easily work on all elements of the board

- Thermal optimisation: very good management of hot spots thanks to the absence of trunking

- Durable: the board does not use faceplate-type accessories. It adapts to your constraints and combats the obsolescence of equipment ranges

Discover EVOBLOC in video

Traceability and compliance

A nameplate identifies the chassis after quality control to ensure traceability, including in CMMS tools.

Our wiring standard is drawn up in full compliance with best practice and EN 61439. It defines the rules for installing switchgear in equipment (marking, wiring, wire colour, wire routing and terminal blocks).

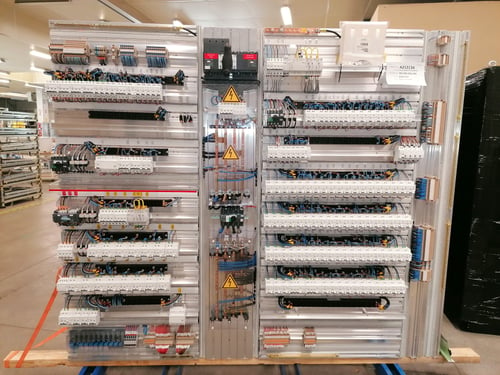

All divisional distribution equipment, placed in closed technical ducts, will be of the COMECA EVOBLOC type. Between each aluminium rounded profiled plate, the system must be composed of guided wiring passages adaptable in section every 50 mm to guarantee the cleanliness of the cabling, lighting, a support for a CMMS technical inventory label as well as COMECLIC® type upgradeable live row distributors.

For even greater installation safety and electrical availability, combine the EVOBLOC solution with a GALAXIS or TITAN main LV board.

This global solution (divisional distribution + main LV board) preserves the homogeneity of the hospital's main distribution system, while maintaining redundancy in the outgoing feeders and the interchangeability of plug-in drawers (IS333) between the different buildings.

Find out more about GALAXIS and TITAN electrical switchboards.