Comeca renovates and modernises two LV switchboards for the petrochemical sector

In a global approach to service continuity, it is important to have a reliable, durable, maintainable and upgradeable installation. Renovating and modernising your LV switchboard thus extends its’ lifespan while guaranteeing its’ operation. Carrying out this work helps to control expenditure on ageing infrastructure.

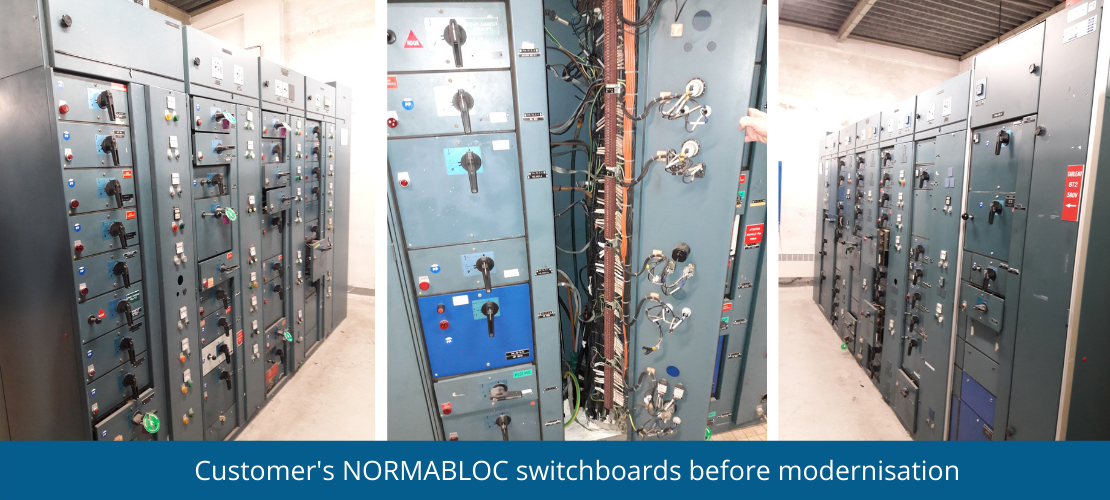

In the case study below, our Comeca Services teams have carried out a renovation and modernisation project of two Low Voltage switchboards for one of our clients, a major player in the petrochemical industry.

Customer issue: extending the life of its LV switchboards

The project presented concerned NORMABLOC switchboards that were more than 20 years old and whose service life our customer wanted to extend. When the unit is shut down every 5 years, our customer wanted to take advantage of this to modernise them and upgrade their electrical diagram.

Our client's objectives were multiple:

- Replace obsolete equipment such as differential relays and electrical equipment in the feeders.

- Renovate without the need to modify the existing cables

- Equip the direct incomers with a current measurement and a protective relay.

- Minimise outage times: 5 days per switchboard

- Limit activity in the substation

- Maintain interchangeability with existing equipment

Recommendations from our experts

Following the audit of the LV switchboards and the clients’ needs, we agreed on a number of recommendations.

Maintenance of the installation

Level 4 and 5 preventive maintenance with a complete check of the busbars and replacement of the bolts. Systematic replacement of the terminal blocks located in fixed parts and intended for the connection of power cables.

Renovation / Modernisation

The use of TREP washers to ensure the tightness of the electrical connections and the ability to compensate for expansion. The installation of current transformers on the direct incomers for protection by SEPAM and an IS signalling card in the feeders.

Example of IS signalling card on a GALAXIS switchboard

Renovation of the measuring compartment with the replacement of the protection and the addition of a central measuring unit.

The addition of auxiliary contacts in the feeder columns to meet the needs of the new control and command scheme. Replacement of the existing functional units with new FUs comprising the latest generation equipment and ensuring interchangeability with the existing equipment (identical power pinout) as well as replacement of the connection doors and top panels.

Modernisation of the scheme: integration of the control and differential protection directly into the feeder.

Comeca Services support

Upstream preparation work in the factory

Under the responsibility of a project manager, the following actions were carried out

- Electrical and mechanical studies based on the client's survey

- Updating and validation of the electrical diagram files

- Procurement of components and manufacture of new functional units

- Manufacture of the new connecting doors and top panels

- Production of an operating procedure and a risk analysis for the prevention plan

Course of the project

A preparatory and planning meeting was held with our site manager and the project manager. The work on site was carried out in 5 consecutive days:

- Removal of obsolete equipment

- Preventive maintenance on the busbars

- Installation of additional equipment: current transformers, measuring station and auxigaines

- Replacement of feeder connection blocks (terminal blocks)

- Replacement of feeders

- Mechanical and electrical functional tests

- Assistance with commissioning

In summary

After 5 consecutive days of work on site, Comeca's teams commissioned the renovated and modernised NORMABLOC LV switchboards.

By carrying out this service we ensured our customer interchangeability with the existing equipment, current measurements and protection relays on the direct incomers as well as the replacement of obsolete equipment. Thanks to this renovation, our customer was able to extend the service life of its low-voltage switchboards.

In order to meet the requirements of the petrochemical sector, Comeca Services will ensure the durability and continuity of service of the installation through preventive maintenance.