Infography: 4 checks on the electrical panel before a change of process

Before adding new equipment to your process, it is necessary to check that your electrical installation is adequate to supply it.

To do this, find in this article an infography of the 4 points of verification must be carried out on your electrical panel before proceeding with the evolution of your processes.

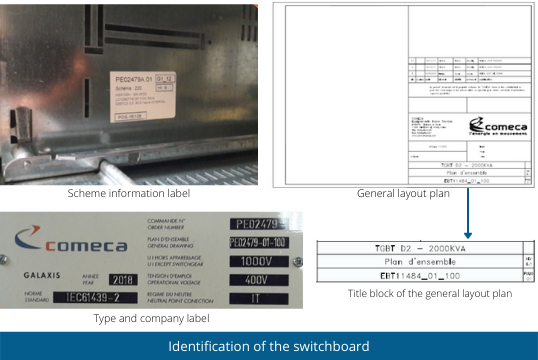

1. The switchboard identification

To begin with, you need to gather the identification information and send it to the manufacturer:- Find the name and contact information of the manufacturer and check if they still exist*.

- Find the order number and the number of the general layout plan.

- Or be in possession of the file of drawings (including the schemes and SLD) and the characteristics of the switchboard.

*If the manufacturer is no longer in business, ask another manufacturer about the possibility of evolution.

2. Available power of the switchboard

It is important to carry out a measurement campaign to perform a power survey. The central measuring station or meter recovers the consumption history and provides the maximum power used. Thus, you know your current maximum need before adding new devices.

Please note: the power is limited by the transformer's power.

Example: The switchboard is sized for 2500A. The current used is 1800A. There is still 700A available. However the transformer limits the available current (1600KVA - 2253A).

3. Available reserve feeders

It is necessary to check the available feeders in the board or in warehouse stock.Please note: The use of reserve feeders available in stock is an emergency solution to temporarily compensate for the delay in supplying new feeders.

Generally these feeders are intended to guarantee the continuity of service of your installation in the event of a breakdown.

4. Available current of the busbar

In order to add feeders an inventory of unequipped power reserves must be made.Please note: It is important to check the capacity of the branch busbar (column), i.e. the admissible current by comparing the characteristics given by the manufacturer with the current already consumed.

This can be done either by carrying out a one-off measurement with a clamp meter or by measuring the power drawn on each feeder.

Infography to share or print:

4 checks to do on your electrical panel before changing your process